Design studies on advanced warships

At present the Division has taken an initiative of research and design studies in an effort to develop the engineering concept of advanced corvette and destroyer. The new hull architecture developed by the initiative of the Division provides a basis for further feasibility analysis in terms of specific ship projects.

An application for the invention «Displacement

Reference list of expert design reviews of ships, vessels and marine vehicle prototypes:

Development of documentation for formulation of the Russian Federation State Program «Development of shipbuilding» (2012).

In the development of documents for shaping up the Russian Federation State Program «Development of shipbuilding» the Division is responsible for the foresight analysis of naval shipbuilding.

State-

In support of this program the methodology was elaborated to validate the plans for development of advanced R&D in the field of shipbuilding, integrated analysis approach to evaluation of the future improvement directions for naval ships. Based on foresight methods the goals and key directions in the naval shipbuilding were formulated for the R&D

Analysis of main trends in foreign navies up to 2020 (2008)

At the request of the Russian Federation MoD we performed a state-

The project focused on the navies of the USA and other NATO countries, Japan, Australia, Sweden and China. The development of other world’s major fleets was also scrutinized.

Updating of regulatory technical documentation

Investigations to examine the ways for raising the technical & economic efficiency of ships, optimization of processes in development, delivery, operation, maintenance and decommissioning of naval technologies throughout the life cycle to meet the state-

Analysis of the Russian & foreign experience to identify the requirements and generate the regulations, standards, norms and technical documentation covering all phases of naval technologies’ life cycle. Formulation of the program for relevant activities in this field up to 2011. Some specific regulatory documents and guidelines were drawn up under research project «Kristallizator».

One of the most important regulatory document developed under this project is the «Main Terms of Ship Acquisition for MoD» (to replace the outdated document issued in 1983 before the Russian Federation became an independent state). The purpose of this document is to regulate the relationships between MoD organizations (customers) and industries (suppliers) regarding the contractual obligations (deadlines, quantities, quality). This document has been agreed by all concerned parties and submitted to the Government for final approval.

Customer — Russian Federation MoD.

Drawing up of Regulations on ship & vessel design & construction (2010–2011)

The Regulations define the procedure and work content in design and construction of ships and vessels, regulates the relationships between state customers, ship designers and builders, and federal authorities responsible for the state policy and regulation regarding the military industrial complex.

The Regulations were elaborated with involvement of research institutes, design bureaus, ship repair and shipbuilding yards, equipment suppliers, etc., on the one hand, and state customers’ and federal authorities, on the other hand.

The Regulations were approved by the Military Industrial Commission of the Russian Federation Government on 24 May 2011.

Customer — Ministry of Industry & Trade of the Russian Federation.

Experimental investigation of ship cable combustion (2012–2013)

A series of experimental studies were conducted at the fire test facility of KSRC to determine the combustion characteristics of typical elements of combustion load components.

The first stage of experiments focused on ship cables of various grades.

The research was aimed to determine:

Experimental data was used to plot flame propagation speed and mass burning rate versus heat flow density on specimens, exposure time and orientation of specimen in space.

Customer — CDB ME RUBIN.

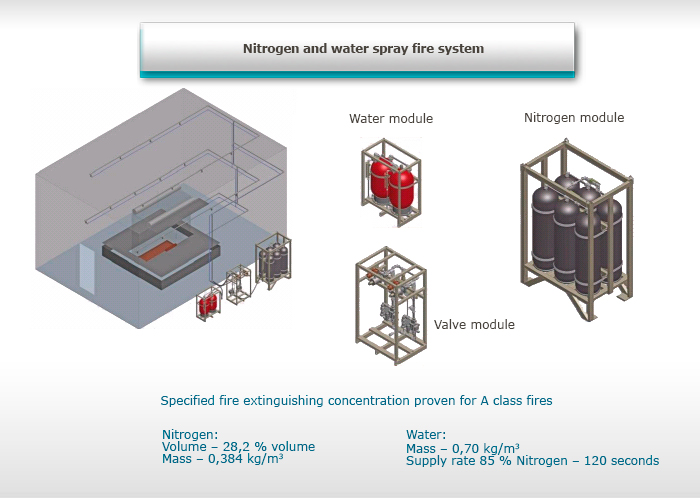

Development of new generation fixed

It was a

The following fixed

The above systems are suing safe fire extinguishing agents like nitrogen, water, fluoride,

The tests confirmed the

Customer — Ministry of Industry and Trade, Russian Federation.

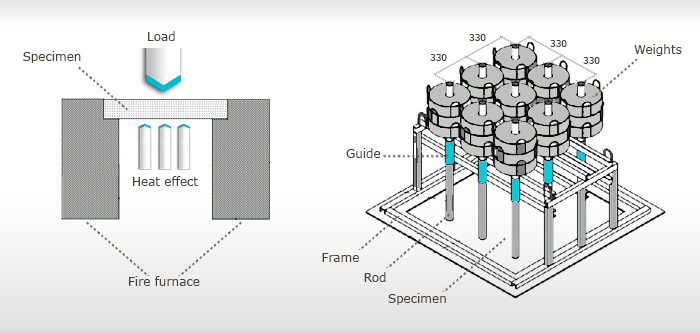

Proposals for optimization of fire protection on ships with hull structures made of polymer composite materials (2009–2011)

Experimental and theoretical studies were performed to determine the strength of ship hull structures made of polymer composite materials (PCM) exposed to elevated temperatures during fires.

General recommendations were given regarding fire safety measures for ships and vessels with PCM hull structures.

The main hazard in this case is lower resistance to elevated temperatures caused by fire accidents as compared to traditional steel structures.

Customer — CISM Prometei.

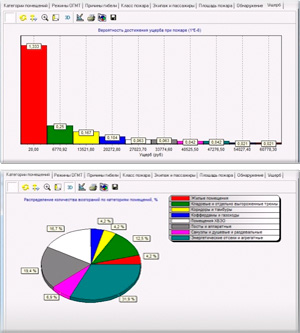

A package of software & methods was developed for formal fire safety appraisal of civil ships and vessels (2009–2011)

The purpose was to create the methods and software to be implemented in shipbuilding practices as a technology for formal safety assessment (FSA).

FSA technology presents a rational and systematic approach to risks assessments for shipping. This approach was called for in view of accident statistics at sea as well as inadequacy of regulations, which cannot cover all specific features of engineering structures. The purpose of FSA is to assess the cost implications and merits of design solutions in terms of risks mitigation.

The FSA methods have long been developed at the international level. The main distinction of the proposed FSA procedures is the use of computer simulation of the fire propagation based on the electronic ship model for developing the fire accident scenario and analysis of the accident consequences.

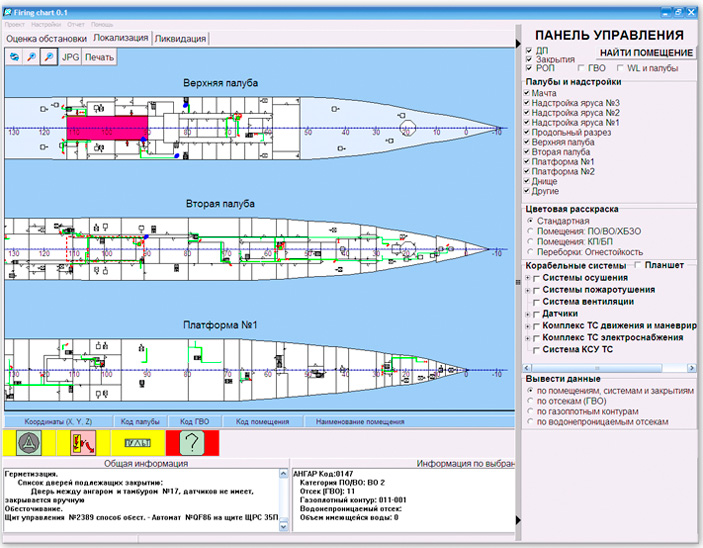

Electronic panel of accident manager on board the ship (2007–2009)

The electronic panel is an analogue of hardcopy documents issued by designers to support

The electronic panel is able to store large amount of data with easy access to the relevant information. Unlike other known means of information support, this tool enables prompt response to varying accident conditions and gives advice based on the current situation.

As the operator inputs data on accident development, he is automatically displayed prompted:

At the operator’s request the deck plans may also indicate locations of

Electronic panel is also able to generate a package of documents issued by designer in support of accident prevention.

Customer — Federal Agency of Industry.

Customers and contractors

The Division has maintained

JSC SPBM MALACHITE

JSC CDB ME RUBIN

JSC Severnoye Design Bureau,

JSC Nevskoe Design Bureau

JSC Almaz Central Marine Design Bureau

JSC Zelenodolsk Design Bureau

JSC Iceberg Central Design Bureau

JSC Alexeev Central Hydrofoil Design Bureau

FSUE Central Research Institute of Structural Materials «PROMETEY»

JSC Afrikantov Experimental Design Bureau for Mechanical Engineering

JSC Kaluga Turbine Plant

JSC Zavod

JSC NPO Saturn

JSC Special Boiler Design Bureau

JSCo «PO Sevmash»

JSC Concern «Avrora»

JSC Concern CSRI Elektropribor,

JSC Concern Gidropribor

JSC Concern Okeanpribor

JSC Concern

JSC «Academician

JSC GNPP «Region»

JSC Admiralty Shipyards

JSC Baltyisky Zavod

JSC Shipbuilding & Shiprepair Technology Center

JSC Concern

FRPC OJSC ‘RPA ‘Mars’

JSC Central Scientific Research Institute «KURS»

FSUE Andreev Acoustic Institute

JSC NPP Raduga

JSC Sukhoi Design Bureau

JSC BERIEV Aircraft Company

JSC Yakovlev Design Bureau

JSC Kamov

Federal Center for

FSUE GosNIILC Raduga OKB «Agat»

FSUE GNC RF TRINITI

JSC VNII Transmash

JSC State Research

FSUE

The Division keeps good business relations with the leading R&D institutions of MoD:

Kuznetsov Naval Academy

Naval Shipbuilding & Weaponry Research Institute (1st TSNII MoD)

Research Institute for Operational & Strategic Studies (24th TSNII MoD)

4 NIU NIC АТ & В 4 TSNII MoD

Rescue & underwater technology Research Institute (40 GNOI MoD)

46th TSNII MoD and many other institutions