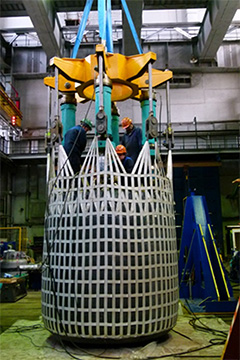

Tests of the world’s largest flexible container

The Krylov State Research Centre has conducted unique tests of the world’s largest flexible container engineered and manufactured by Flexible Bulk Container Corporation:

Material |

Rubberized fabric reinforced by a network of strips |

Max. lifting weight, kgf (Qмакс) |

14000 |

Capacity (max), м3 |

13,0 |

Top |

Closed with loading hose |

Bottom |

Flat and solid with discharge hose |

Lifting gear (number of slings) |

8 |

Liner |

No |

Total number of stack tiers |

4 |

Dimensions, сm |

240×240×280 |

Packaging group |

III |

Reg. number |

11213691 |

Static tests were conducted equivalent to lifting of a 14t container with top slings, the maximum overload factor of 6. The container sustained the proof load.<

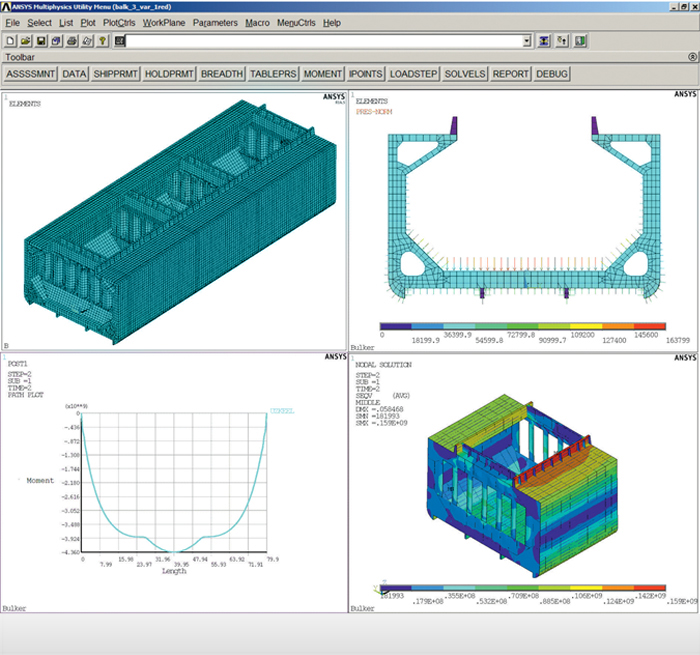

Software for verification of the ultimate and fatigue strength of bulker and tanker hull structures based on the unified IACS rules

The software was developed to enable

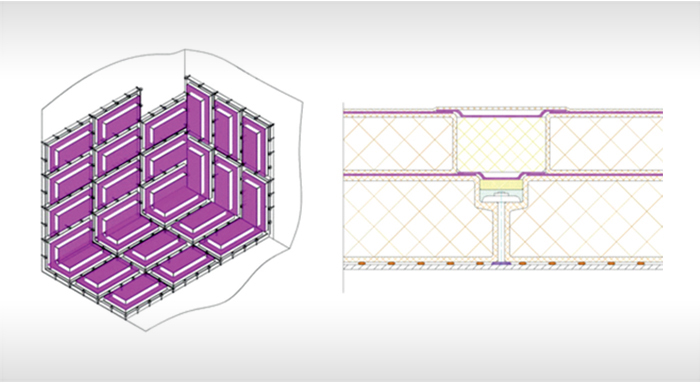

Polymer composite cargo containment systems of membrane type for LNG storage and shipping

The structural design and production concept was developed for manufacturing of polymer composite cargo containment systems of membrane type for LNG storage and shipping to enable improved heat insulation and structural reliability as well as simplified production processes and shorter installation time.

New efficient tool for

Main advantages:

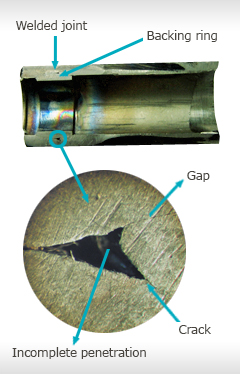

Acoustic emission tests to check the erection welds of air & gas pipelines on submarines under construction at Admiralty Shipyards

The purpose of these tests was to check the quality of erection welds in air & gas pipelines on submarines under construction during pneumatic strength trials of the pipelines using the acoustic emission techniques.

The acoustic emission tests are performed using

The AE inspections supported the acceptance of air & gas pipelines of 01570 & 01339 Projects.

Composite vibration isolation

Innovative design of composite vibration isolation couplings has been devised featuring high dissipative properties with substantial reduction of dynamic loads on ship shaftings and power plants induced by unsteady ship motions.

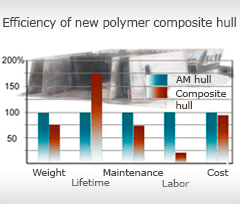

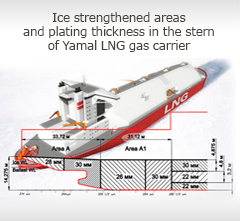

New ice belt design for

Results achieved:

OUR MAJOR CUSTOMERS:

High quality of our work has been validated by the long history of domestic fleet.

High competence and developments of the Krylov Centre are acknowledged by numerous Russian and foreign research centers, classification societies and companies.

Various theoretical and experimental studies are being performed, sophisticated applied problems are being solved upon the orders of our customers.

Ministry of Industry and Trade of the Russian Federation

Rosoboronexport JSC

Central Research Institute of Structural Materials «Prometey»

SPBM Malachite JSC

CDB ME Rubin JSC

PO Sevmash JSCo

Zvezda JSC

SSTC JSC

Admiralty Shipyards JSC

Almaz Central Marine Design Bureau JSC

Severnoye Design Bureau JSC

Zelenodolsk Design Bureau JSC

Iceberg Central Design Bureau JSC

Central Oil equipment Design Bureau Gazprom JSC

Baltsudoproekt Central Design Bureau

Research and Design Technological Bureau Onega

Intari LLC

NIKIET JSC

KBSM JSC

Lukoil —

Shipyard Yantar JSC

Gazflot JSC