Electric engineering & technology

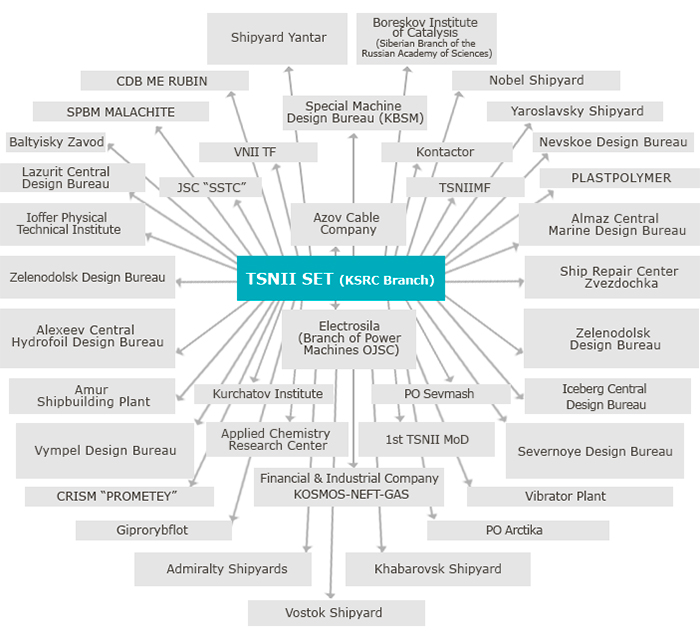

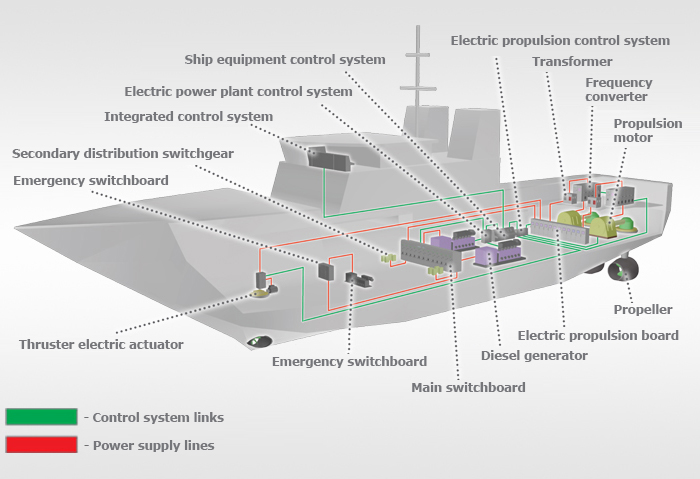

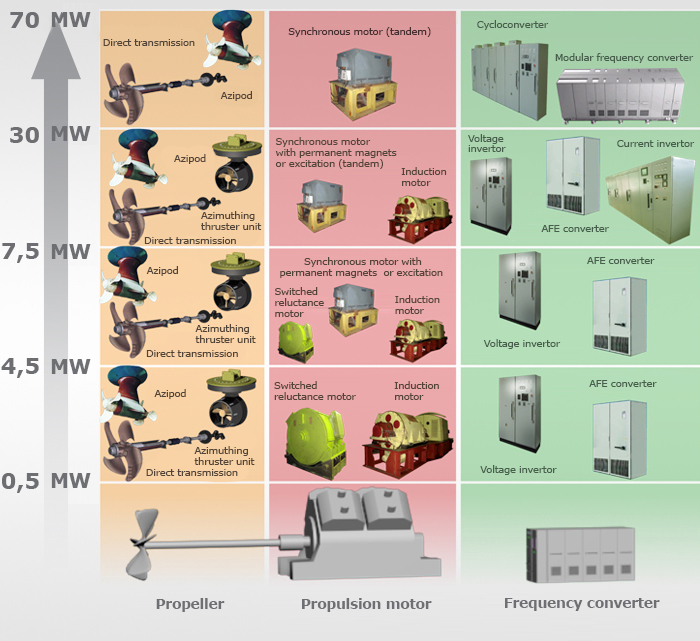

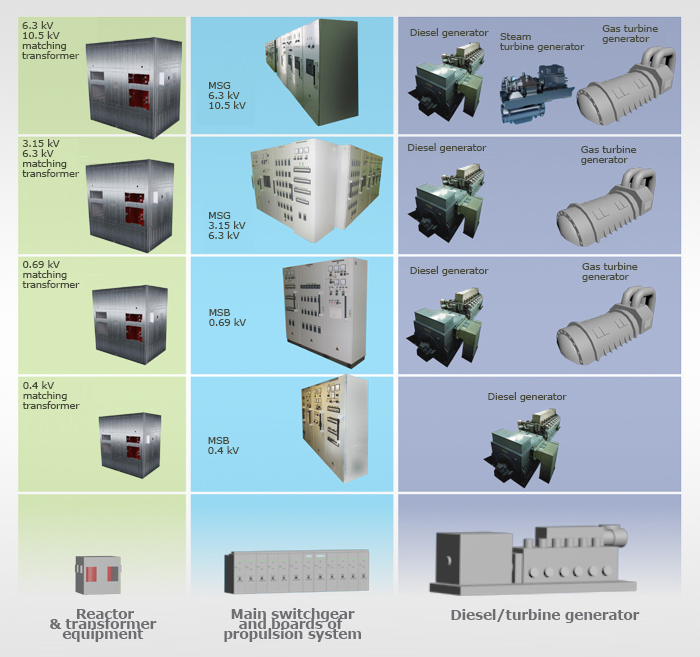

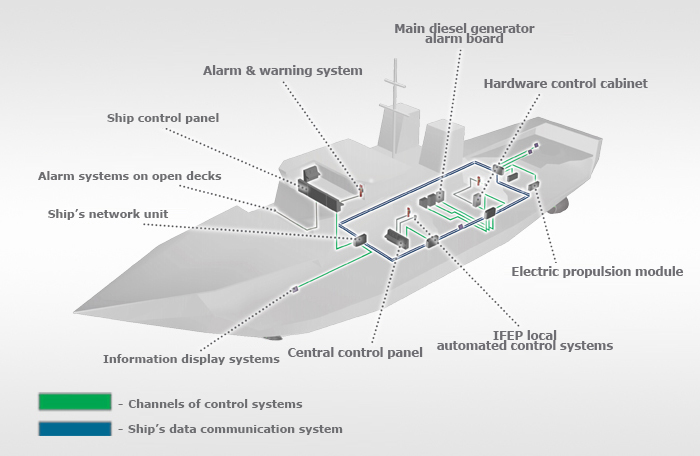

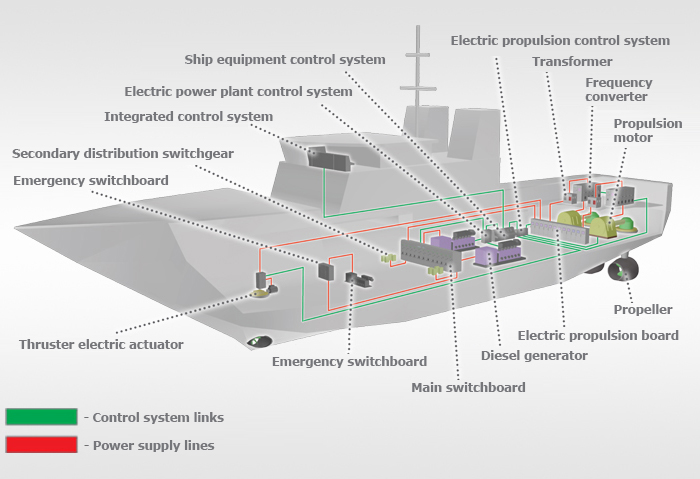

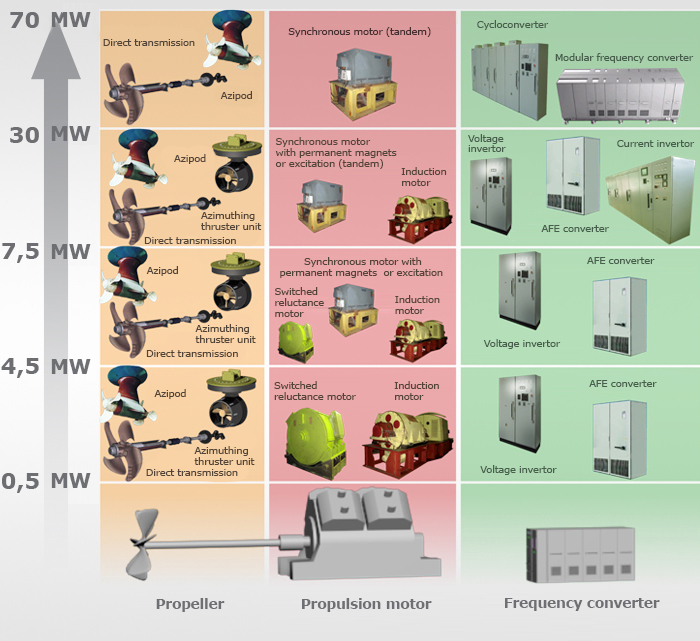

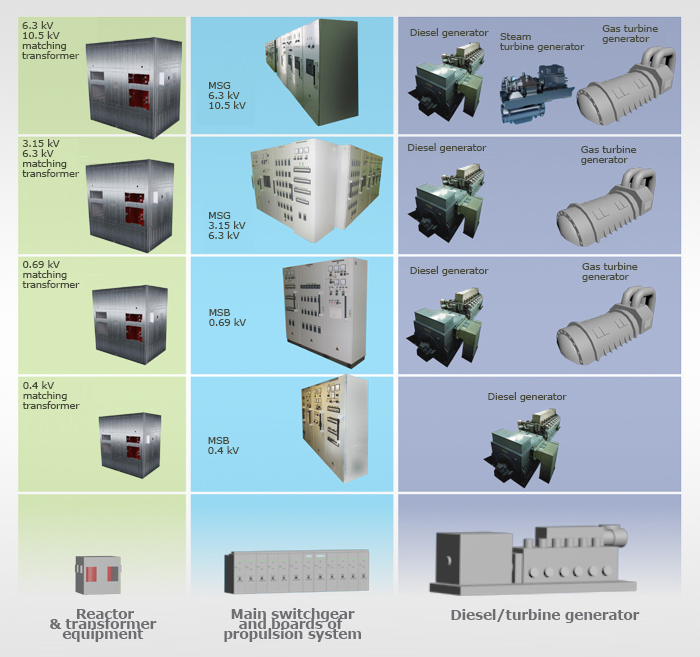

We have a great experience in design, production, tests, delivery & on-board adjustment of fully electric propulsion systems (integrated electric power systems with electric propulsion). These systems are integrated complexes of gears and electric equipment with the common source of electric power for supply of propulsion units and shipboard users. TSNII SET has produced, tested and installed fully electric propulsion systems on tugboats (projects 745 & 22030), hydrographic survey vessels (projects 19910 & 19920), rescue vessels (projects 21300 & 20180).

TSNII SET is continuously improving the integrated electric propulsion systems. Our R&D efforts are focused on tackling practical issues. The projects performed under federal target programs (funded from the state budget) and contracts with customers are based on consistent and goal-oriented approach. TSNII SET developments include:

- ship electric propulsion systems with a power range of 1.5–8.5 МW delivered at propeller;

- ship electric propulsion systems with a package of electric equipment for pod, power output up to 3.5 MW;

- engineering design projects with running mock-up models of automated local control systems for fully electric propulsion systems intended for a range of ship types;

- techniques & hardware for protection of fully electric ships against uncontrolled behavior at tripping of converters and propulsion motors.

There is an on-going process of developing the monitoring technologies and systems for technical diagnostics of electric equipment of integrated electric propulsion systems for commercial ships and marine structures, effort are undertaken to develop the integrated electric propulsion systems of 5–25 MW, voltage 6.3 kW.

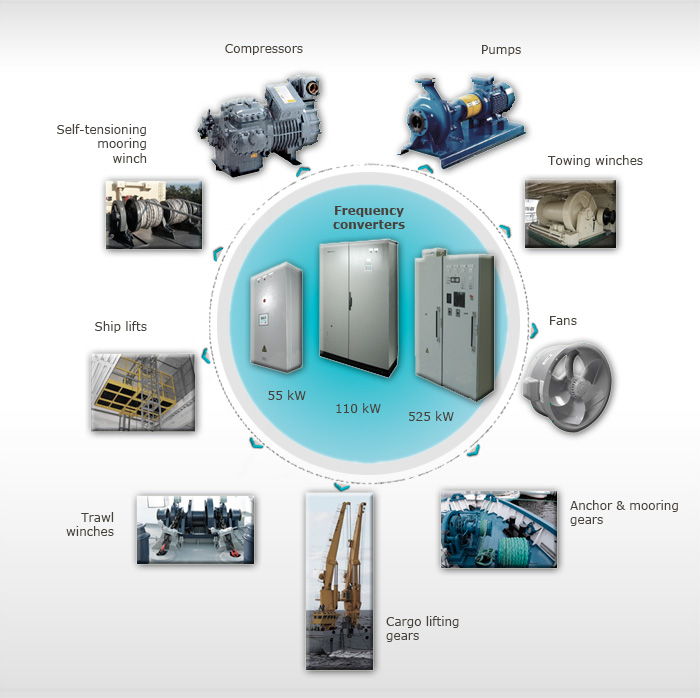

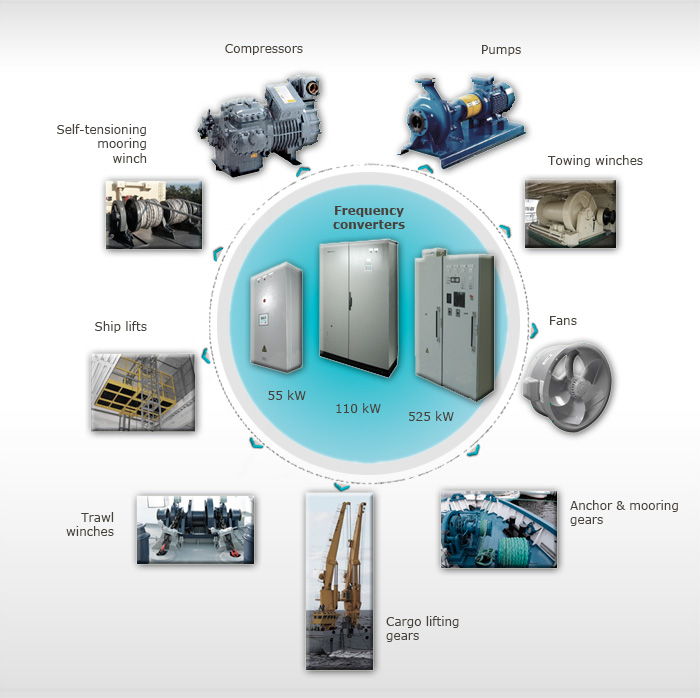

TSNII SET is also actively engaged in developing individual electric equipment for ships, vessels and marine structures:

- static converters of various types for power range 50–3000 kW;

- main switchboards for low (under 1000 V) and high (above 10 500 V) voltage;

- emergency switchboards;

- sub-switchboards for voltages under 1000 V;

- automated control systems for individual machines, electric power systems and entire processes;

- package of frequency-controlled motors for various machinery of platforms, power output 5–700 kW.

TSNII SET is also a leader in the development of structural/mounting details (water-tight entries, penetrations, cable connections, etc.) as well as on-board installation techniques. This kind of fittings were supplied to deep-water submersibles of projects 16810 and 16811 (the latter beat the diving depth record for Russian underwater vehicles — 6270 m).

In this area TSNII SET is continuously improving structural/mounting arrangements based on R&Ds. We have worked out and continue to develop installation techniques for novel halogenless cables noted for higher reliability and fire safety, industrial processes for large-scale production of flameproof tight penetrations for inter-compartment transit of power and weak-current cables.

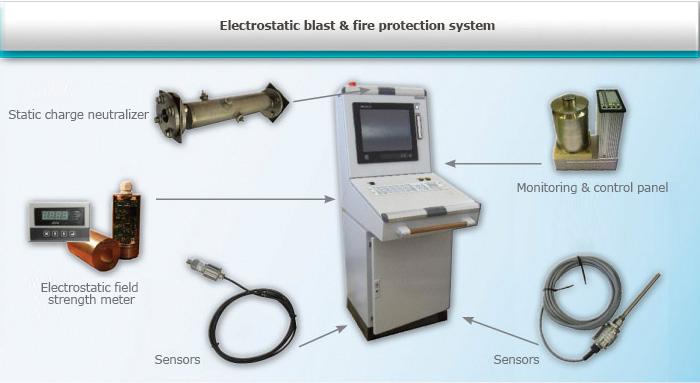

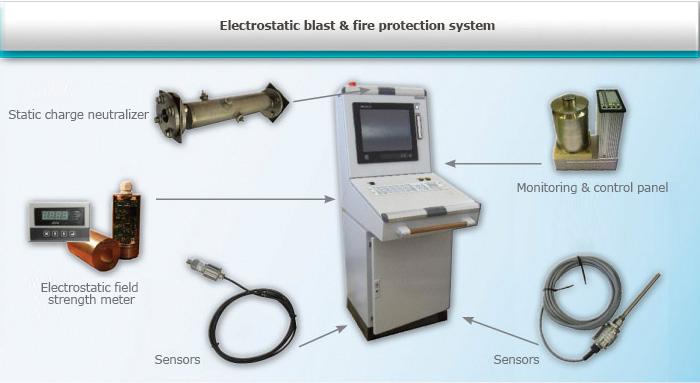

Another promising field is development of electrostatic blast & fire protection. We have developed an electrostatic blast & fire protection system for storage and transportation of crude oil and oil products produced off-shore.

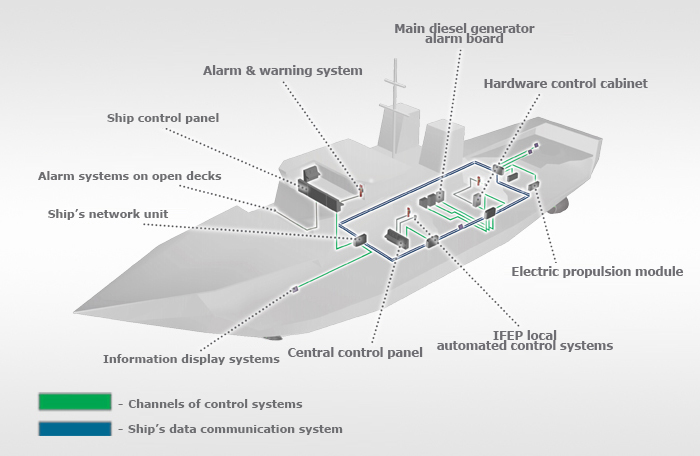

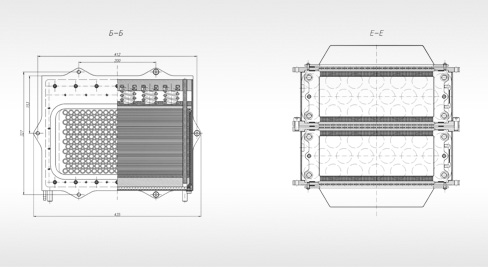

Modular concept of integrated full electric propulsion (IFEP) systems

The modular IFEP concept is based on standard electric equipment modules, which can be assembled to build up the desired system. The modular concept makes it possible to use a minimum number of standard equipment units to configure powering systems with customized specifications (power, voltage).

The modular IFEP design combined with advanced power estimation techniques enable optimization of the ship powering architecture as suites best the type and design specifications of the ship in question.

Advantages of modular IFEP design:

- Reduced cost and duration of design.

- Easy-to-manufacture IFEP system.

- Easy to upgrade and repair.

- Higher reliability of IFEP system.

- Standard and unitized parts of system.

- Easy to configure IFEP system to match any required voltages and tasks using a standard set of hardware.

Ship’s Fiber Optic Digital Data Network (FODN)

Ship’s fiber optic digital data network is made up of ship’s data communication units (DCU) located in the key ship compartments equipped with intelligent devices and automatic hardware. The intelligent devices are linked to DCU with copper duplicated communication lines arranged within one compartment.

FODN is intended to ensure reliable data exchange between all networked devices. Ethernet interface is used for data communication. The double-loop configuration with two independent fiber optic loops ensures robustness of the network. Data are sent by program via two (primary and backup) channels and can also be received from two channels. The data received from the channel currently assumed to be the primary one is accepted as valid. In case of failure in communication with any network unit the channels are switched. This feature provides enhanced reliability because each network unit is able to operate via either channel at different sections of the data transfer line.

Advantages:

- common use, versatility and compatibility with modern controllers, computers and other smart devices;

- convenient and high-speed transmission of large data volumes;

- independent of line length (with reference to ship dimensions);

- immunity to electromagnetic interferences;

- high level of reliability and robustness;

- fully functional even in case of multiple circuit breaks at different locations or failure of any network unit;

- self-diagnostic function.

Hydrogen power engineering

TSNII SET has many years of experience in the development of fuel-cell power plants including special-purpose systems, we operate up-to-date research & production facilities and test sites and have a stock of forward-looking solutions in the field of hydrogen power engineering. The notable projects accomplished in recent years are:

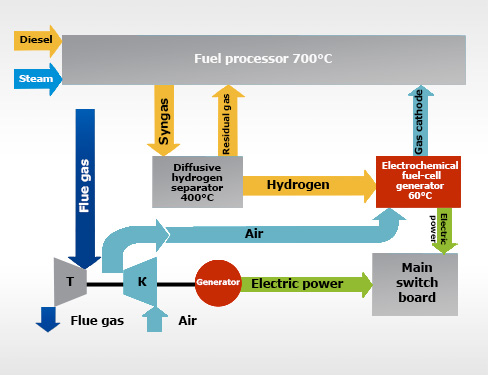

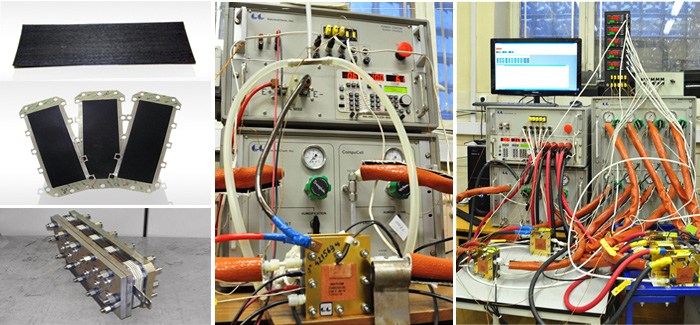

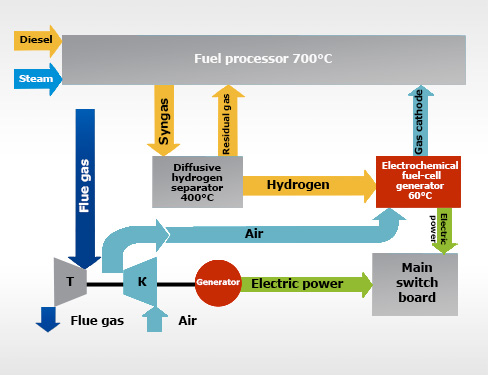

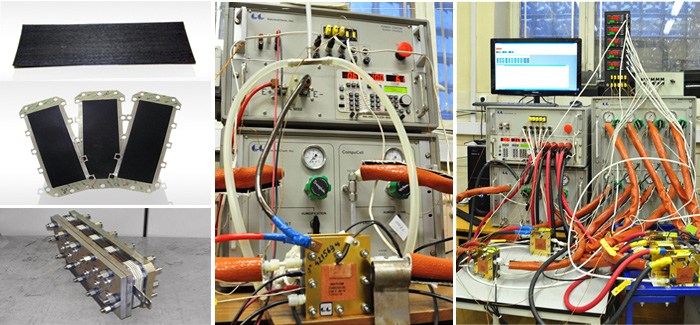

R&D «Hybrid power plant with solid polymer fuel cells»

In 2011, under the federal target program «Development of civil marine technologies for 2009 — 2016», we have completed the project in development of a ship hybrid power plant in the power range of 250 — 2500 kW.

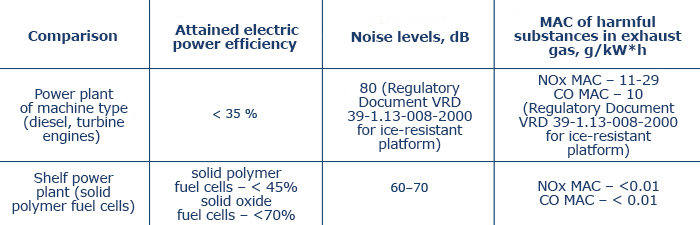

Hybrid power plants with solid polymer fuel cells (SPFC) are primarily intended for ships projected for oil & gas prospecting, production and shipment in the Far North. The main advantages of SPFC hybrid plant as compared to diesel-generator, gas engine and gas turbine plants are as follows:

- low operation costs due to the highly efficient electro-chemical conversion of thermal energy (efficiency of electro-chemical generator ~ 50%) combined with efficient waste heat recovery using conventional machine converters (efficiency of electro-chemical generator + 20%) as well as the possibility of using the carried hydrocarbons as own fuel;

- high maneuverability of electrochemical generators in the entire load range;

- drastic cut-down of harmful emissions.

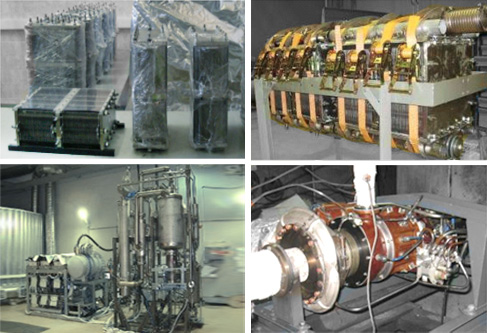

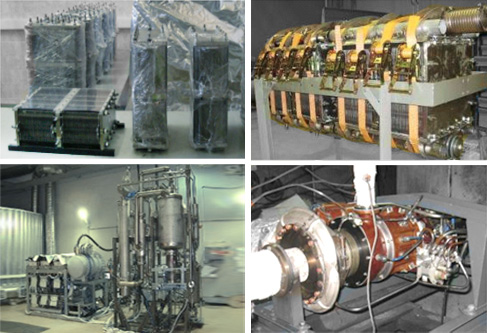

A demonstrator model of 60 kW hybrid ship powerplant module was produced on the basis of a highly-maneuverable low-temperature electrochemical generator with solid-polymer fuel cells (МGEU-60). It presents the basic design solution intended to produce a range of hybrid (combined) powerplants for ships operating on hydrocarbon fuel.

R&D «Advanced auxiliary powerplant»

This R&D project was started in June 2012 under the federal target program «Development of civil marine technologies for 2009 — 2016» (subject: Development of domestic proton-exchange membrane fuel-cell batteries and powerplants operating on natural gas & air).

The purposes of this R&D project are:

- to develop domestic technologies for producing fuel-cell batteries (FCB) with proton-exchange membrane (PEM) and fuel-cell powerplants operating on natural gas and air intended for self-contained power supply to on-shore pipelines of offshore gas-producing facilities;

- generation of leading-edge scientific & engineering solutions related to fuel-cell powerplants, primarily intended for gas carriers and tankers.

In 2012 we completed the preliminary and detailed design of a demonstration model of the auxiliary powerplant based on PEM fuel-cell battery, we made and tested breadboard prototypes of PEM fuel-cell battery and natural gas converter assemblies, identified the list of imported technologies to be replaced by Russian made products, analyzed the features of technologies to be developed and prepared a program for co-operative work, we also performed feasibility studies to support our developments.

The outputs of this R&D project:

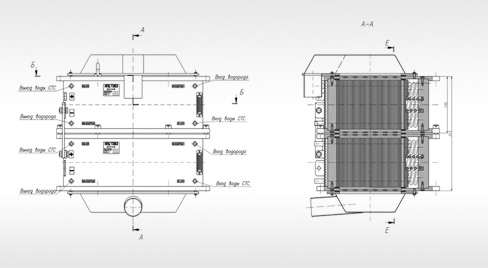

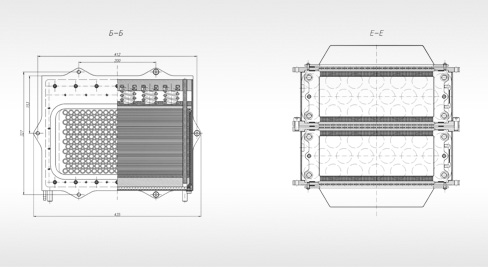

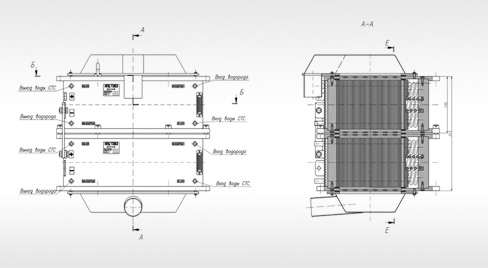

1. Prototype PEM fuel-cell battery of 5kW (BTE-84). Design documentation.

2. Demonstration model of BTE-84-based auxiliary power plant of 10 kW (kilowatt power rating).

To be completed in 2014.

R&D «Power plant for Shelf»

This R&D project was started in June 2012 under the federal target program «Development of civil marine technologies for 2009 — 2016» (subject: Development of MW-rated electrochemical power plant for ships and marine structures operated in waters and coastal areas subject to strict environmental regulations).

The purposes of this R&D project are:

- improvement of powerplants intended for ships of various types and power supply of offshore gas-producing facilities;

- development of MW-rated electrochemical powerplants based on PEM fuel-cell batteries running on natural gas and air for various ship types and offshore gas-producing platforms to achieve high efficiency and environment-friendly operation with comfortable noise levels.

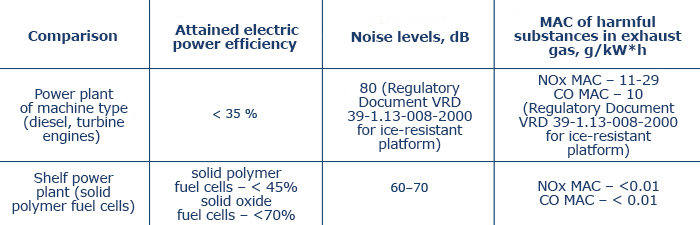

Power efficiency and environment merits of electrochemical powerplants based on PEM fuel cells:

Under Phase 1 completed in 2012 we made the preliminary design of PEM fuel-cell powerplant, converter for steam natural gas reforming with membrane extraction of hydrogen, and bench powerplant module. We have developed documentation for design of breadboard assemblies of PEM powerplant, and then manufactured and tested breadboard assemblies of PEM powerplant.

The outputs of this R&D project:

1. Prototype PEM fuel-cell battery of 50kW (BTE-50B) for MW-rated powerplant. Design documentation.

2. Bench module of 50 kW for MW-rated powerplant based on BTE-50B

To be completed in 2014.

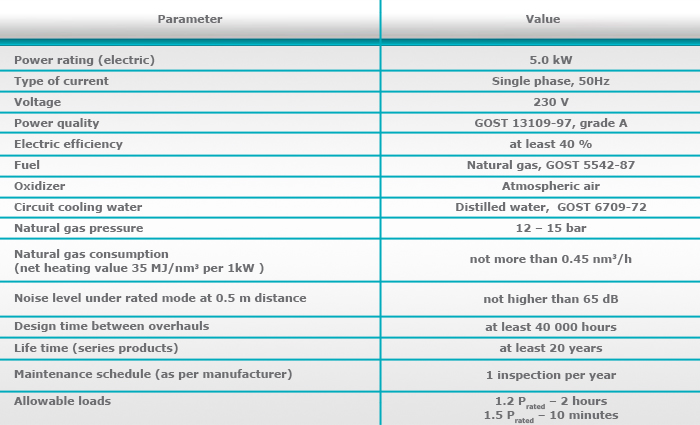

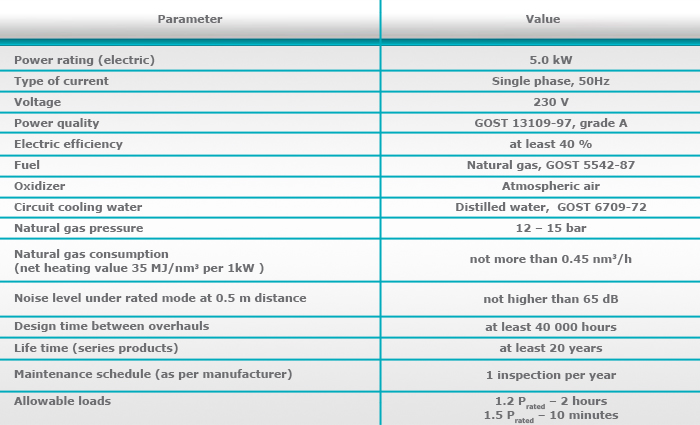

Self-contained fuel-cell powerplant of 5.0 kWe

Advantages of self-contained power supply sources:

- cost-efficient power supply solution for undeveloped grid infrastructure;

- reduced consumption of energy resources, lower maintenance costs and, hence, lower costs of power generation for remote consumers due to renewable energy sources;

- flexibility to use various types of power sources in different combinations to suit specific local requirements;

- automatic control system for remote monitoring and control of the power plant using wire or wireless communication links.

Design and main data:

The power generation unit assembled and tested on manufacturer’s site is a metal block-box made up of heat-insulated sandwich panels containing:

- electrochemical generator of up to 10 kW;

- power conversion & distribution system (main switchboard and local distribution board);

- heating/cooling system;

- gas hook-up module (optional);

- ventilation system coupled with gas control system and H2 detector система;

- fire alarm and access control system;

- gas fire suppression system;

- lighting system;

- automated control system providing remote control and data communication to top level;

- backup power supply (optional).