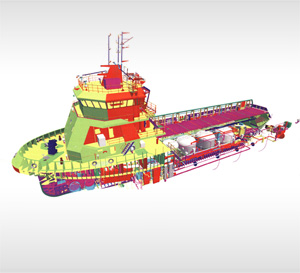

Development and delivery of

Customers — JSC Severnaya Verf, JSC Shipyard Yantar, JSC Ship Repair Centre Zvezdochka, JSC SPBM MALACHITE, JSC Almaz Central Marine Design Bureau and JSC Severnoye Design Bureau.

Basic design of Kaskad MP system has been elaborated. It is a

Customer – JSC CDB ME RUBIN

Industry standard OST5R.0754–2012 «Ships & marine structures. Rules of magnetic compatibility in design, construction, operation of ships and marine structures, development & delivery of equipment» has been elaborated, approved and introduced since

A series of EMC tests have been performed on naval ships and at equipment manufacturers’ sites using a portable EMC test system developed at the Krylov Centre. Customers – JSC Academician

Overheat detectors for threaded joints of ship electric equipment have been developed to support diagnostics of fire hazardous situations. These instruments enable visual detection of slack threaded contracts during operation. Joint commercial production of the detectors is planned in association with JSC Krizo. Customer – Ministry of Industry and Trade, Russian Federation.

Preliminary design of an integrated accident monitoring system has been worked out for the offshore Arctic oil & gas fields. The system is based on fixed- and

Hydrophysical measurements have been performed using Krylov’s

An experimental prototype of portable instrumentation system, first-of-

Customer – Ministry of Industry and Trade, Russian Federation

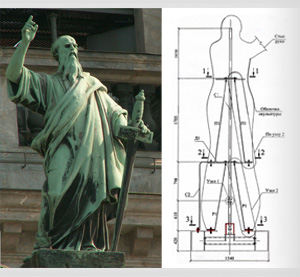

Saint Isaac’s Cathedral Restoration Project: electrically insulated mounting details for two statuary groups the Apostol Paul and Angels with lampion have been developed, manufactured and installed to protect steel framework from contact corrosion.

Customer – The State Memorial Museum St. Petersburg SAINT ISAAC’S CATHEDRAL

The 2nd phase of R&D project Noise under Federal Target Program «Development of Civil Marine Technologies».

Under this phase KRSC has completed the basic design of type systems for cancelling ELFE and normalizing the permanent magnetic field in ships and other marine platforms to meet permissible levels required by the Sanitary Code.

The strongest ELFE sources in ships are components of ship’s electric grid: cables, boards and powerful distribution and switching gears. The level of electromagnetic emissions generated by such devices is governed by current amplitudes in electric circuits, while the absorbed currents are defined by the load changing during ship operation.

ELFE levels are efficiently reduced using automatic cancelling technique. Experimental studies on a breadboard model of such system confirmed its advanced capabilities. Presently, a test prototype of the system is being manufactured.

The permanent magnetic field in the compartments of ships and other marine platforms needs to be normalized because its levels are lower than the natural level of the Earth’s magnetic field, which may have detrimental effect on crew performance and health. Weakening of the permanent magnetic field depends on the specific location of ship’s compartment, structural materials as well as geographical location of the ship herself.

The system designed for normalizing the permanent magnetic field in ship compartments to reach the levels prescribed by relevant regulations is using an assembly of circuits arranged around the «ceiling» and «floor» perimeter to generate a sufficiently uniform field within the given compartment so that its level is close to the Earth’s magnetic field.

A stable current source has been developed for the electric circuits with low current ripple and adjustable settings. The magnetic field density is monitored using a